- Home Page

- Company Profile

-

Our Products

- Distillation Column

- Distillation Column Internals

- Pan Type Liquid Distributor

- Bed Limiters

- Pipe Type Liquid Distributor

- VEP Type Liquid Distributor

- Multibeam Type Packing Support

- Grid Type Packing Support

- Vane Type Liquid Collector

- Chimney Tray Type Liquid Distributor

- Column Packing

- Distillation Column Internal

- Trough Type Liquid Distributor

- channel Type Liquid Distributor

- Chimney Tray Type Liquid Collector

- Gas Sparger

- Wedge Wire Screen

- Reactor

- Mixing Technology

- Static Mixer (V-Type Element)

- IBC Tank Agitator

- Static Mixer (X-Type Element)

- Static Mixer (Helical Type Element)

- Static Mixer

- Hydrofoil Agitator

- Side Entry Agitator

- Drum Mixer (Agitator)

- SS Static Mixer

- Static Mixer Element

- MS + PTFE Lining Static Mixer

- FRP Static Mixer

- PVC Static Mixer

- Jacketed Static Mixer

- 2 & 3 Phase Separator

- Pilot Plant System

- Heat Exchanger

- Structured Packing

- Spray Ball

- Storage tanks

- Filters

- Scrubber Column

- Bubble Cap Trays

- Valve Tray

- Distillation Column Trays

- Vacuum Ejector

- Basic Engineering Package

- Random Packing

- Pusher Centrifuge

- Mist Eliminator

- About Us

- Contact Us

- Distillation Column

- Distillation Column Internals

- Reactor

- Mixing Technology

- 2 & 3 Phase Separator

- Pilot Plant System

- Heat Exchanger

- Structured Packing

- Spray Ball

- Storage tanks

- Jacketed Reactor

- Filters

- Scrubber Column

- Bubble Cap Trays

- Vane Pack Type Mist Eliminator

- Valve Tray

- Distillation Column Trays

- Vacuum Ejector

- Basic Engineering Package

- Random Packing

- Pusher Centrifuge

- Mist Eliminator

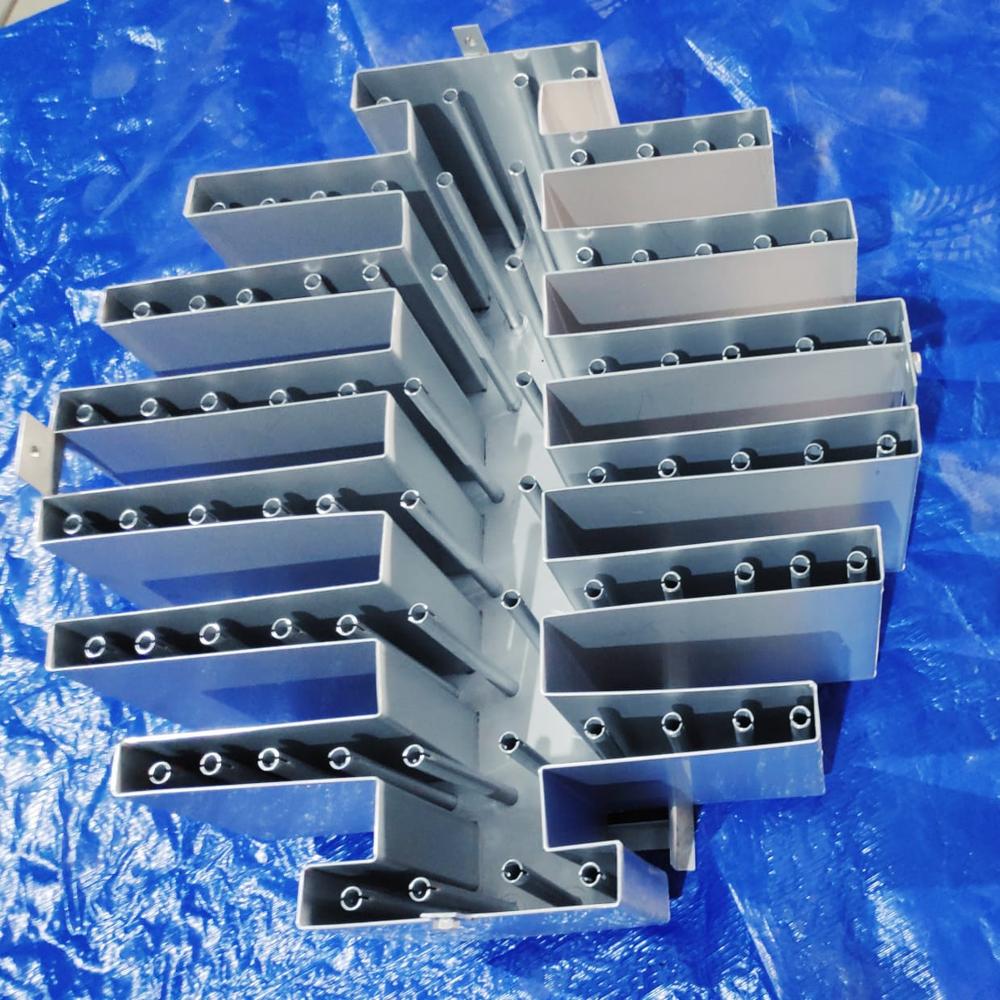

Trough Type Liquid Distributor

25000.0 INR

Product Details:

- Material SS, MS, Duplex

- Computerized No

- Automatic Grade Manual

- Weight 20 Kilograms (kg)

- Dimension (L*W*H) 5005*500*300 Millimeter (mm)

- Warranty 1 Year

- Click to View more

X

Trough Type Liquid Distributor Price And Quantity

- 25000.0 INR

- 1 Number

Trough Type Liquid Distributor Product Specifications

- SS, MS, Duplex

- 1 Year

- 20 Kilograms (kg)

- Manual

- 5005*500*300 Millimeter (mm)

- No

Trough Type Liquid Distributor Trade Information

- Mumbai

- Cash in Advance (CID)

- 1 Number Per Week

- 2 Week

- No

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Middle East, Africa, Asia, Australia, Central America, North America, South America, Eastern Europe

- All India

Product Description

A trough-type liquid distributor uses troughs with lateral notches or orifices to evenly distribute liquid over the packing material in a packed column, ensuring efficient mass transfer in processes like distillation and absorption. It is a gravity-fed distributor that collects liquid from a parting box and directs it into narrow troughs, from which it flows through the orifices onto the packing bed below. Trough distributors are versatile, widely used, and can handle high liquid loads and varying flow rates, with designs available for different applications such as single-stage and two-stage configurations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email