- Home Page

- Company Profile

-

Our Products

- Distillation Column

- Distillation Column Internals

- Pan Type Liquid Distributor

- Bed Limiters

- Pipe Type Liquid Distributor

- VEP Type Liquid Distributor

- Multibeam Type Packing Support

- Grid Type Packing Support

- Vane Type Liquid Collector

- Chimney Tray Type Liquid Distributor

- Column Packing

- Distillation Column Internal

- Trough Type Liquid Distributor

- channel Type Liquid Distributor

- Chimney Tray Type Liquid Collector

- Gas Sparger

- Wedge Wire Screen

- Reactor

- Mixing Technology

- Static Mixer (V-Type Element)

- IBC Tank Agitator

- Static Mixer (X-Type Element)

- Static Mixer (Helical Type Element)

- Static Mixer

- Hydrofoil Agitator

- Side Entry Agitator

- Drum Mixer (Agitator)

- SS Static Mixer

- Static Mixer Element

- MS + PTFE Lining Static Mixer

- FRP Static Mixer

- PVC Static Mixer

- Jacketed Static Mixer

- 2 & 3 Phase Separator

- Pilot Plant System

- Heat Exchanger

- Structured Packing

- Spray Ball

- Storage tanks

- Filters

- Scrubber Column

- Bubble Cap Trays

- Valve Tray

- Distillation Column Trays

- Vacuum Ejector

- Basic Engineering Package

- Random Packing

- Pusher Centrifuge

- Mist Eliminator

- About Us

- Contact Us

- Distillation Column

- Distillation Column Internals

- Reactor

- Mixing Technology

- 2 & 3 Phase Separator

- Pilot Plant System

- Heat Exchanger

- Structured Packing

- Spray Ball

- Storage tanks

- Jacketed Reactor

- Filters

- Scrubber Column

- Bubble Cap Trays

- Vane Pack Type Mist Eliminator

- Valve Tray

- Distillation Column Trays

- Vacuum Ejector

- Basic Engineering Package

- Random Packing

- Pusher Centrifuge

- Mist Eliminator

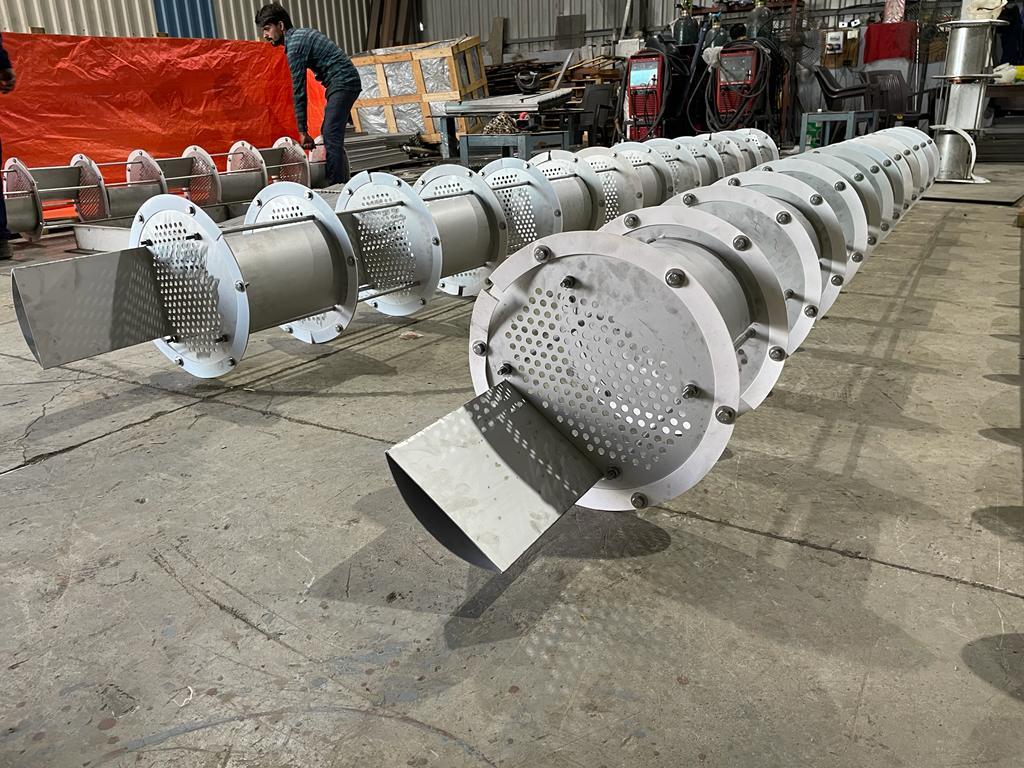

Round Valve Trays

25000.0 INR/Unit

Product Details:

- Condition New

- General Use Industrial

- Material Other

- Computerized No

- Automatic No

- PLC Control No

- Warranty Yes

- Click to View more

X

Round Valve Trays Price And Quantity

- 25000.0 INR/Unit

- 1 Unit

Round Valve Trays Product Specifications

- Industrial

- Yes

- Other

- New

- No

- No

- No

Round Valve Trays Trade Information

- 4 Unit Per Day

- 2 Week

Product Description

Tray used in Distillation Column for making contact between a gas phase and a liquid phase so as to bring them as close as possible to the equilibrium state. Tray columns are widely used in various types of mass transfer operations. All the simulation results, which predict a certain number of theoretical stages, can be converted to actual trays depending upon tray efficiency for a particular service. In any conventional tray vapor rises through the liquid pool on the tray deck and then disengages from the liquid in the space above the deck. Liquid enters the tray from a downcomer above and leaves via a downcomer below.We also supply Cartridge type Sieve Trays Assembly.

For more information kindly visit our website: www.orcinus.in

Reliable Processing Equipment for Industry

These Round Valve Trays are built to handle demanding industrial processing tasks, delivering consistent results through semi-automatic operations. With quality-assured MS construction and a carefully engineered design, they provide dependable performance and maximize productivity across various industries.

Assured Warranty and Trusted Supply

Customers benefit from assured warranty support when purchasing our Round Valve Trays. As leading exporters, manufacturers, suppliers, and traders in India, we prioritize quality and customer satisfaction, ensuring your machinery investments are secure and beneficial for years to come.

FAQs of Round Valve Trays:

Q: How are the Round Valve Trays operated in industrial settings?

A: Round Valve Trays function in a semi-automatic manner, which allows operators to manage essential processing steps without the need for advanced computerization or PLC controls. Their simple operation makes them accessible across various industrial environments.Q: What materials are used in the construction of these trays?

A: These trays are constructed using high-grade mild steel (MS), offering enhanced durability and resistance to wear common in industrial processing applications.Q: When should I consider using these processing machines?

A: You should consider using Round Valve Trays when you require reliable machinery for medium to high volume industrial processing tasks, particularly where fully automated or computerized options are not essential.Q: Where are these Round Valve Trays supplied from?

A: We export, manufacture, supply, and trade these Round Valve Trays from India, serving industrial clients both nationally and internationally.Q: What is the operational process for these Round Valve Trays?

A: Operators load the materials into the machine, manage the processing using manual controls, and oversee valve operation as required, ensuring efficient workflow without full automation.Q: What are the main benefits of choosing semi-automatic Round Valve Trays?

A: The main advantages include cost efficiency, straightforward operation, long-term durability due to quality MS material, and warranty back-up, reducing maintenance concerns and production downtime.Q: How can these trays be used to improve industrial processing?

A: Their standard size and rugged construction make them suitable for integration into existing workflows, enhancing throughput and reliability for processing tasks in various sectors.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free